- Company

Company

- Business

Business

- R&D

R&D

- Media Center

Media Center

- Location

Professional Organization of

World best Engineering ResourcesHumanity, Technology Pioneer, Value CreationRolled Steel Plate Geometry Measuring Instrument [Shapemeter System]

-

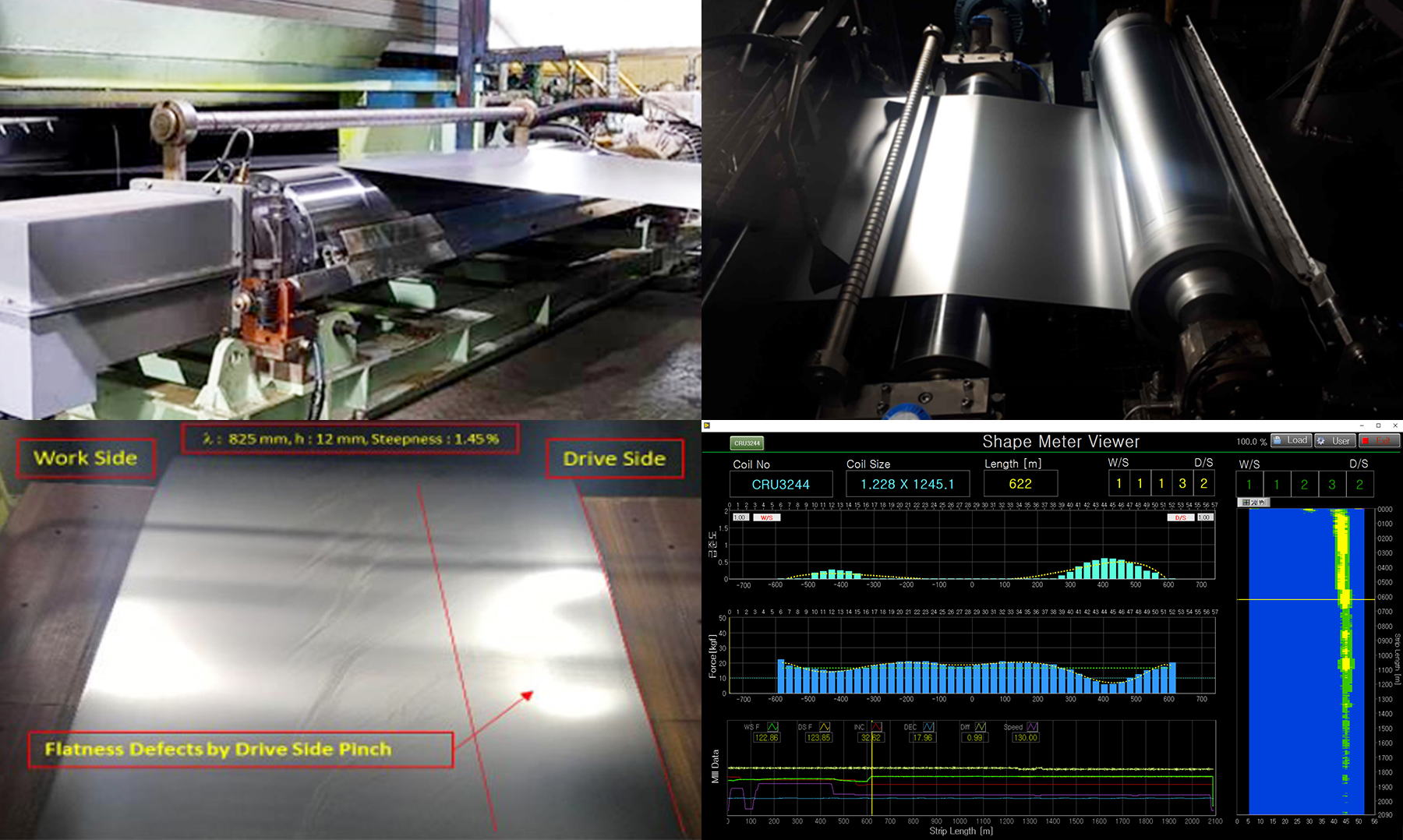

Continuous Annealing Line

-

Inter Stand PCM

-

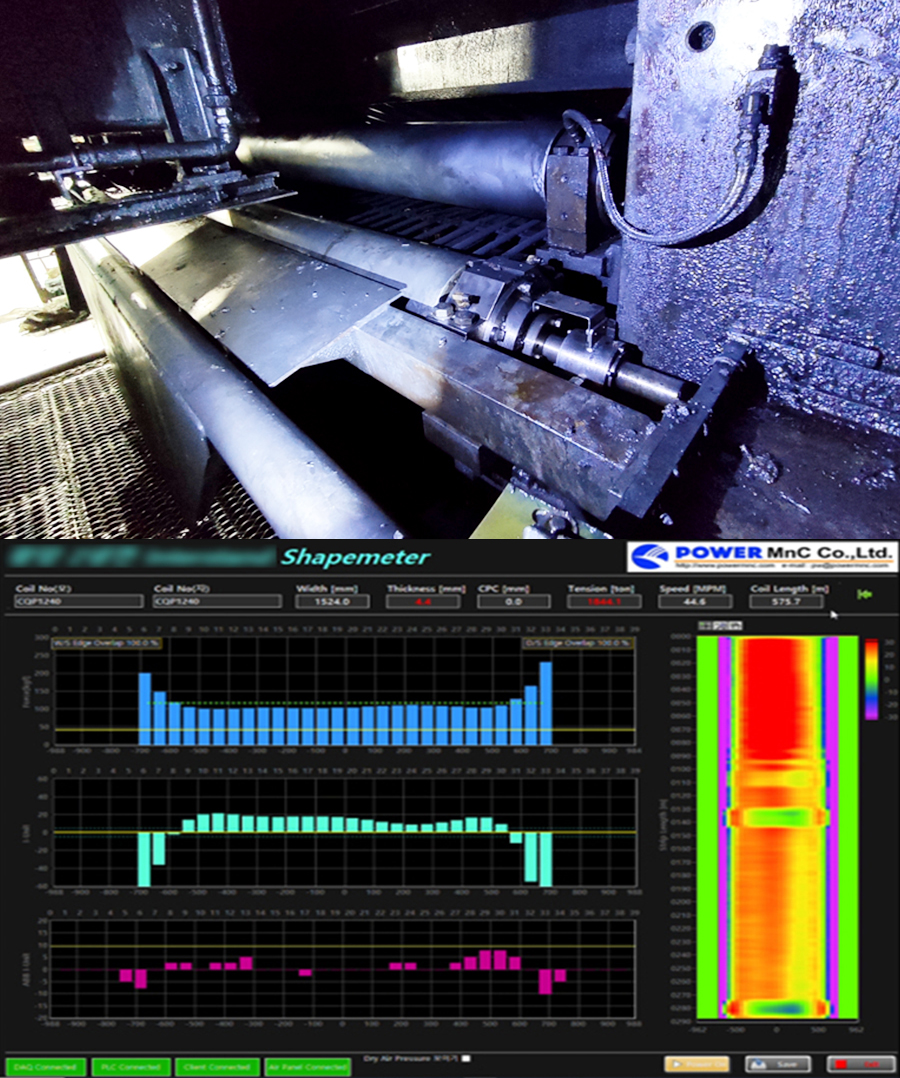

AL CRM

A realtime measuring system designed to prevent shape from being deformed when running strip tension drops by revealing the final and actual shapes of the stripes rolled without time delay

-

Shape Measurement Screen

PR Movie

-

Features

- Able to measure and analyze in realtime

- Checks a plate shape intuitively

- Able to check previous measurements

- Eliminates a plate surface defect at acceleration and decelerates

- Speed control and synchronization through torque control

- Reduces bearing friction loss

- Reduces the moment of inertia

- Prevents roll acceleration

Specifications

Introduction Standard Roll / Seamless Roll Foil Roll Life of Shape Meter >20 years >20years Strip Thickness 0.1 to 10mm 0.005 to 0.5mm Accuracy (Depends on Installation) 0.5I-Unit 0.5I-Unit Parallel Resolution (Width of Section) 26 or 52mm 52mm Measurement Range (Tension/Section) 10 to 60,000N 1 to 1,000N Maximum Mechanical Load (Tension/Section) 120,000N 20,000N Dynamically Measurable Force Change/Section 0.7 to 1 N 0.02 to 0.03N Working Speed Max 4,000m/Min Max 4,000m/Min Measurement Frequency 4 Times per one rev 4 Times per one rev

- Business